Updates

First machined bevel!

Well it took me all day and 7 test blades but I finally got the bevel fixture tuned in and working nicely!

The texture you see on the blade can't be felt at all with your fingertips, should sand out very quickly! The tip will be getting by hand on the belt grinder, then blended into the rest of the blade!

Because the bevel angle is so shallow if something is off even 0.001" it will be very noticeable. I had to lap 0.0015" off one side of the back of the fixture to tune the angle in to perfection!

Really pleased this worked out so well, wasn't really sure it was going to work at all!

#knifeclub #knifemaking #knifemaker #cnc #instamachinist

Photo by Aaron Gough on June 24, 2015.

See the original post and comments on Instagram

The texture you see on the blade can't be felt at all with your fingertips, should sand out very quickly! The tip will be getting by hand on the belt grinder, then blended into the rest of the blade!

Because the bevel angle is so shallow if something is off even 0.001" it will be very noticeable. I had to lap 0.0015" off one side of the back of the fixture to tune the angle in to perfection!

Really pleased this worked out so well, wasn't really sure it was going to work at all!

#knifeclub #knifemaking #knifemaker #cnc #instamachinist

Photo by Aaron Gough on June 24, 2015.

See the original post and comments on Instagram

First bevel machining fixtures!

The finished bevel fixture. It holds two blades at a time so the the bevels can be partially milled on the CNC.

There are locating pins to precisely position each blank. There will be clamps that go on top at the tang and at the tip to hold everything in place during machining.

Pleased with how it's come out so far! Whether or not the process will actually work is still an open question! I'll find out soon!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 23, 2015.

See the original post and comments on Instagram

There are locating pins to precisely position each blank. There will be clamps that go on top at the tang and at the tip to hold everything in place during machining.

Pleased with how it's come out so far! Whether or not the process will actually work is still an open question! I'll find out soon!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 23, 2015.

See the original post and comments on Instagram

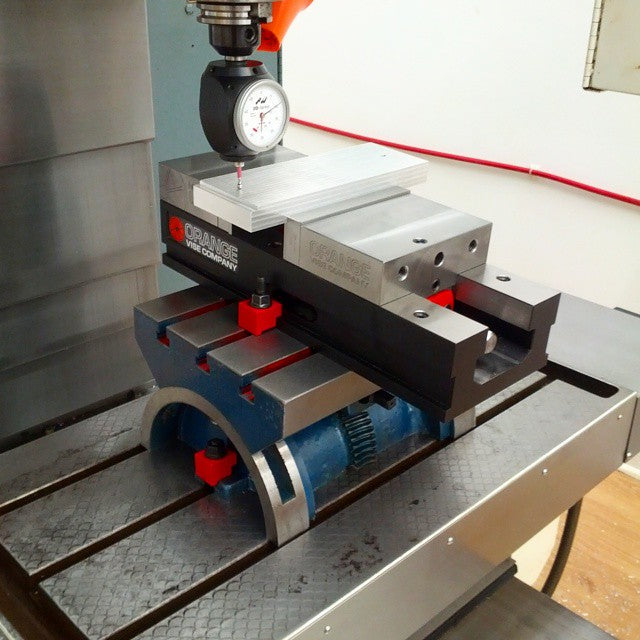

Machining at an angle.

Setting up to cut a precision angle fixture for beveling blades at precisely 3.4°

Total pain to setup, but luckily I should only have to do this a few times, then the fixture I'm making will do the work in the future!

#cnc #instamachinist #orangevise

Photo by Aaron Gough on June 23, 2015.

See the original post and comments on Instagram

Total pain to setup, but luckily I should only have to do this a few times, then the fixture I'm making will do the work in the future!

#cnc #instamachinist #orangevise

Photo by Aaron Gough on June 23, 2015.

See the original post and comments on Instagram

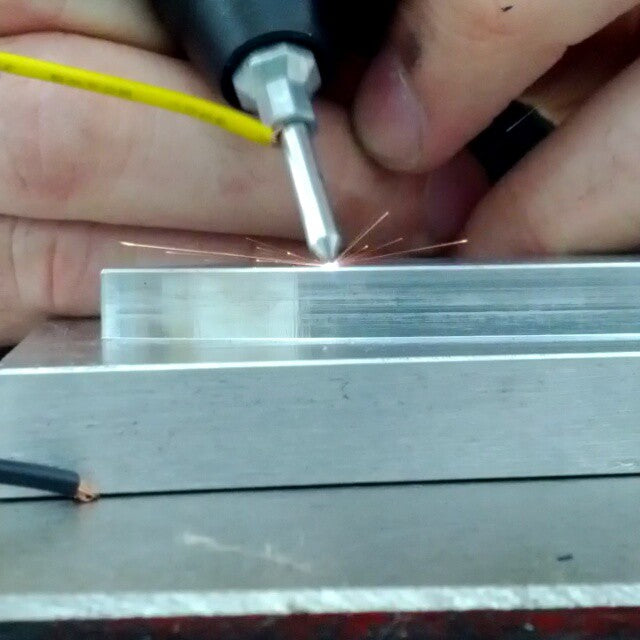

Trying out carbidizing!

I lashed together a homebrew carbidizer using a computer power supply and my Dremel impact engraver, using it to add some carbide 'grit' onto the end of the fixture so that the blades can't move side to side once they're clamped down... Seems to be working surprisingly well!

See the original post and comments on Instagram

See the original post and comments on Instagram

New blade machining fixture!

Nearly finished making a new clamping caul for the fixture I use to profile the blades!

When the bolts are fully tightened up it flattens out and applies all that spring force to hold down the steel near the tip so I can hopefully solve my chatter issues. If this doesn't work then I'll likely have to try vacuum clamping.

The caul is made from A2 tool steel and is just about to go in the kiln for hear treating up to spring hardness so that it will keep its shape for a long time to come!

Getting all this stuff sorted out really does take a lot of work!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 21, 2015.

See the original post and comments on Instagram

When the bolts are fully tightened up it flattens out and applies all that spring force to hold down the steel near the tip so I can hopefully solve my chatter issues. If this doesn't work then I'll likely have to try vacuum clamping.

The caul is made from A2 tool steel and is just about to go in the kiln for hear treating up to spring hardness so that it will keep its shape for a long time to come!

Getting all this stuff sorted out really does take a lot of work!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 21, 2015.

See the original post and comments on Instagram

Destruction of a nice endmill.

This is what the end of a nice endmill looks like after you snap it in half from chatter!

Seems like the edges failed from the chatter, then it started melting the steel which stuck in the flutes and them BAM off it went flying round the shop!

Luckily this is just a little guy, only 0.1875" in diameter.

Photo by Aaron Gough on June 20, 2015.

See the original post and comments on Instagram

Seems like the edges failed from the chatter, then it started melting the steel which stuck in the flutes and them BAM off it went flying round the shop!

Luckily this is just a little guy, only 0.1875" in diameter.

Photo by Aaron Gough on June 20, 2015.

See the original post and comments on Instagram

First Resolute MkIII blade blank!

Hot off the VMC!

This is one of the prototype Resolute MKIII blades made with the new toolpaths. Came out beautifully and is within 0.0005" of the ideal size!

The new toolpaths include machining of the window breaker which you can see down at the bottom, very pleased with how that came out!

I need to get some special tools made to help deal with chatter when machining near the tip. Because the steel is flexible there I have to machine pretty conservatively which annoys me immensely. If I can get some 'downcut' bits made in the right size then I should be able to machine it much more aggressively!

Learning a ton doing this and having lots of fun!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 20, 2015.

See the original post and comments on Instagram

This is one of the prototype Resolute MKIII blades made with the new toolpaths. Came out beautifully and is within 0.0005" of the ideal size!

The new toolpaths include machining of the window breaker which you can see down at the bottom, very pleased with how that came out!

I need to get some special tools made to help deal with chatter when machining near the tip. Because the steel is flexible there I have to machine pretty conservatively which annoys me immensely. If I can get some 'downcut' bits made in the right size then I should be able to machine it much more aggressively!

Learning a ton doing this and having lots of fun!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 20, 2015.

See the original post and comments on Instagram

A 'test standard'.

Very happy with how this came out! It's a 'standard' that defines the size of the Resolute MKIII handle and tang! It's accurate to 0.0001" and will let me make very quick tactile checks to make sure that my tangs and handles are exactly on size. The tangs are easy to measure, but the handle scales aren't which prompted me to make this!

The position of the pin holes in both the tang and handle scales are also critical and this standard makes it easy to quickly check that in a qualitative fashion.

The edge of the handle scale must be within 0.0005" of the edge of the tang for it to feel 'flush' (human fingers are very sensitive!) so I really need to keep my tolerances very close to get the fit and finish that I want!

#knifeclub #knifemaking #customknives #knife #cnc #instamachinist

Photo by Aaron Gough on June 19, 2015.

See the original post and comments on Instagram

The position of the pin holes in both the tang and handle scales are also critical and this standard makes it easy to quickly check that in a qualitative fashion.

The edge of the handle scale must be within 0.0005" of the edge of the tang for it to feel 'flush' (human fingers are very sensitive!) so I really need to keep my tolerances very close to get the fit and finish that I want!

#knifeclub #knifemaking #customknives #knife #cnc #instamachinist

Photo by Aaron Gough on June 19, 2015.

See the original post and comments on Instagram

Failed fixtures...

One of those frustrating days today unfortunately, made a lot of scrap!

Both these fixtures look nice, but they're both wrong in subtle and unfixable ways, this steel is expensive too unfortunately!

Oh well, the next one will be right and then I'll be off to the races!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 18, 2015.

See the original post and comments on Instagram

Both these fixtures look nice, but they're both wrong in subtle and unfixable ways, this steel is expensive too unfortunately!

Oh well, the next one will be right and then I'll be off to the races!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 18, 2015.

See the original post and comments on Instagram

Close-up of CNC machined knife blanks.

First parts coming off the VMC with the new optimized toolpaths!

These are the first stage of the blades for the new Resolute. With the new toolpaths and tools they come off the machine deburred front and back! All pin holes are reamed to precisely 0.1235" to fit my fasteners perfectly.

What you see in this photo is actually the back of the parts as they come off the machine! These knives are going to be as beautiful inside as they are outside! Very exciting!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 17, 2015.

See the original post and comments on Instagram

These are the first stage of the blades for the new Resolute. With the new toolpaths and tools they come off the machine deburred front and back! All pin holes are reamed to precisely 0.1235" to fit my fasteners perfectly.

What you see in this photo is actually the back of the parts as they come off the machine! These knives are going to be as beautiful inside as they are outside! Very exciting!

#knifeclub #knifemaking #cnc #instamachinist

Photo by Aaron Gough on June 17, 2015.

See the original post and comments on Instagram