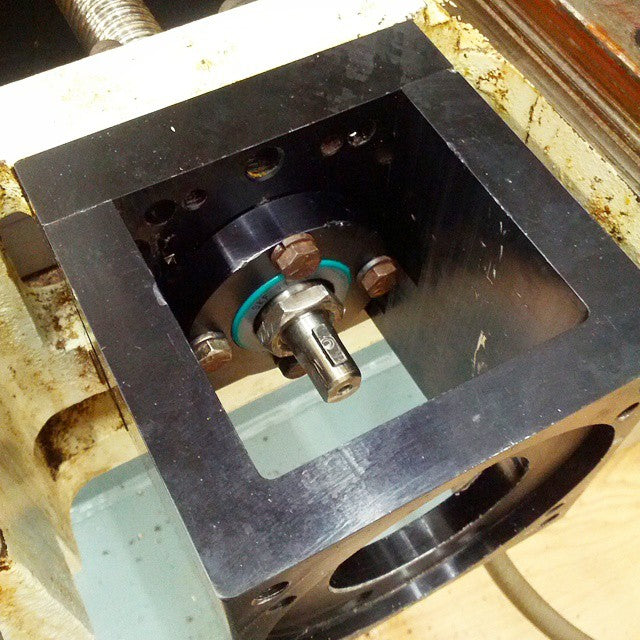

Replacing a Fadal thrust bearing.

This is where I spent basically the whole day, replacing the X axis thrust bearing on the VMC!

I did some tests this morning to find the cause of the poor edge quality that I was seeing on parts made by the machine. Discovered I had 0.0025" of lost motion in the X- direction. This didn't show up in previous tests I had done for some reason.

I had replacement thrust bearings on hand because I knew it was a failure point on these machines, so I pulled the X axis apart and set about the replacement! It took a while because I hadn't done it before. Once I went out and bought the proper wenches it was reasonably straight forward.

Now I'm seeing only 0.0006" of lost motion which is vastly better than it was!

The ballscrew is clearly a bit worn, I will update the backlash compensation settings and see how we go, at the very least it should be much better! If necessary I will replace the ballscrew later in the year.

Getting closer and closer to starting on the first new batch of Resolutes!

#knifeclub #cnc #instamachinist

#machineshop #machinist

Photo by Aaron Gough on June 07, 2015.

See the original post and comments on Instagram

I did some tests this morning to find the cause of the poor edge quality that I was seeing on parts made by the machine. Discovered I had 0.0025" of lost motion in the X- direction. This didn't show up in previous tests I had done for some reason.

I had replacement thrust bearings on hand because I knew it was a failure point on these machines, so I pulled the X axis apart and set about the replacement! It took a while because I hadn't done it before. Once I went out and bought the proper wenches it was reasonably straight forward.

Now I'm seeing only 0.0006" of lost motion which is vastly better than it was!

The ballscrew is clearly a bit worn, I will update the backlash compensation settings and see how we go, at the very least it should be much better! If necessary I will replace the ballscrew later in the year.

Getting closer and closer to starting on the first new batch of Resolutes!

#knifeclub #cnc #instamachinist

#machineshop #machinist

Photo by Aaron Gough on June 07, 2015.

See the original post and comments on Instagram